Palm oil physical refining process(1)

Palm oil physical refining process

The purpose of pretreatment is to remove impurities that are not removable by steam stripping or that would be degraded by treatment. These include, in varying amounts, materials such as phospholipids and trace metals.

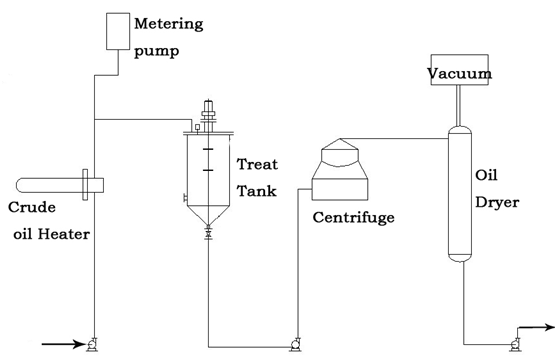

Crude palm oil is continuously pumped under automatic control, through the crude oil heater where it is heated to 190F. metering pumps feed concentrated phosphoric acid and demineralized hot water at controlled rates into a pipeline where they combine to form a dilute phosphoric acid solution.

The heated crude palm oil and dilute phosphoric acid are combined in a pipeline and delivered to the treat tank for thorough mixing.

The acid crude palm oil serves to react with the trace metals and inactivate them and also hydrate the phosphatides forming a second phase.

The oil-acid mixture is pumped to the centrifuge where the hydrated gums are separated from the oil by centrifugal force and discharged into waste water trap. The degummed oil passes to the oil dryer where disdegummed crude palm oil is removed under vacuum. The degummed crude palm oil is now ready for palm oil physical refining process.

Leave A Message

If you want to know more information about Palm oil physical refining process(1) . pls kindly leave your phone number, We will back to you ASAP once we got your message.

-

Guinea client orders 1TPD electric heating palm oil refinery plant from Henan Glory

-

Henan Glory lands Guatemalan order for small scale palm oil processing equipment

-

Henan Glory supplies palm oil processing equipment to its overseas warehouse in Nigeria

-

A repeat Indonesian customer chose Henan Glory for palm oil press machine spare parts order

-

Nigerian client orders a 2tph drum-type palm fruit thresher from Henan Doing Nig. Co.,Ltd

-

200kg/d mini palm oil refining plant: Henan Glory’s new deal in Central Africa

-

-

Shipment Notice: 1tph compact palm oil processing line successfully dispatched to Nigeria

-

Cooperation with Indonesia: Henan Glory to supply 500kg/h palm oil pressing machine

-

Nigerian customer and Henan Doing sealed a deal for palm kernel oil extractors

-

2tph Palm Oil and Palm Kernel Oil Processing Machines Project in Nigeria

-

-

-

1tph palm oil pressing machines successfully installed in Lagos, Nigeria

-

-

-

-

500kg/h palm oil and palm kernel oil processing plant project in Ghana

-

-

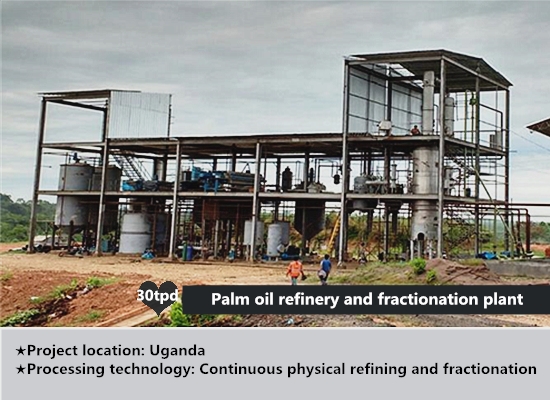

30tpd palm oil refinery and fractionation plant project successfully installed in Uganda