Palm oil mill processing

Palm oil process

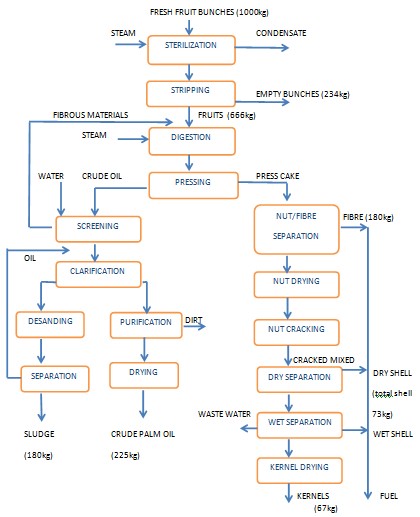

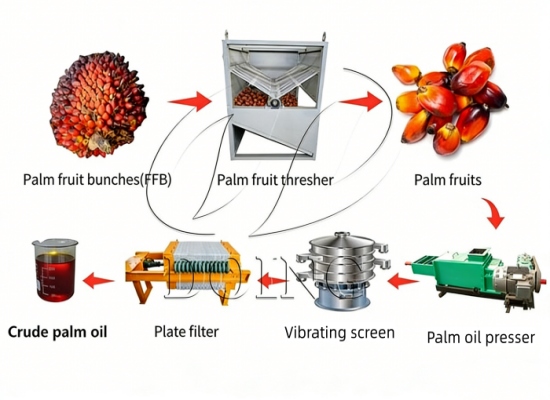

There are many plant seeds containing fat in the world. Palm oil is extracted from fresh fruit bunches by mechanical process. The modern palm oil mill is based predominantly on automatic machinery. The quality of crude palm oil is depended on the care taken after harvesting, particularly on the handling of the palm seeds. Palm oil mill processes are as follows:

This comprises of sterilization, stripping, digestion and pressing, clarification, purification, drying and storage. First, collecting the ripe fresh cluster from the orchard, and then transmit them to the factory. Second is sterilization process. Sterilizing process is crucial to the final oil quality. Sterilization inactivates the lipases in the fruits, and prevents build-up of free fatty acids (FFA). In addition, steam sterilization of the FFBs facilitates fruits being stripped from the bunches. It also softens the fruit mesocarp for digestion and release of oil, and conditioning of nuts to minimize kernel breakage. Third is threshing section. The purpose of threshing is to separate the palm fruit from the FFB.

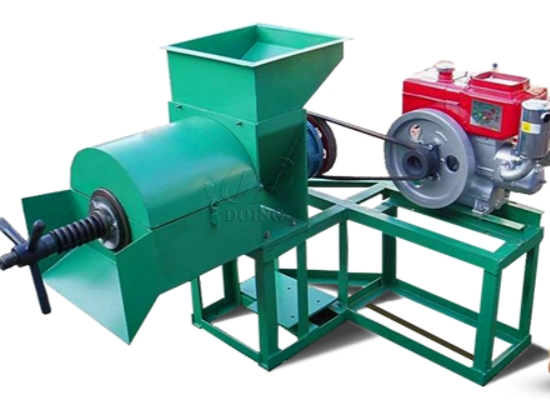

After stripping, the fruits are moved into a digester where, the fruits are reheated to loosen the pericarp. The steam heated vessels have rotating shafts to which are attached stirring arms. The fruits are rotated about, causing the loosening of the pericarps from the nuts. Then, it is sent to continuous screw press. After pressing, the palm oil is divided into two parts: the mixture of oil and the press cake. And then is crude oil clarifying section. Oil from the top is skimmed off and purified in the centrifuge prior to drying in vacuum dryer. The final crude palm oil is then cooled and stored. The lower layer from the clarification tank is sent to the centrifugal separator where the remaining oil is recovered. The oil is dried in vacuum dryers, cooled and sent to storage tanks. All of these are palm oil mill processes.

Leave A Message

If you want to know more information about palm oil extraction machine. pls kindly leave your phone number, We will back to you ASAP once we got your message.

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

-

A Cameroonian client successfully booked a 500kg/h palm oil processing line

-

Successful order for 1tph palm oil processing equipment from a customer in Nigeria

-

Guinea client orders 1TPD electric heating palm oil refinery plant from Henan Glory

-

Henan Glory lands Guatemalan order for small scale palm oil processing equipment

-

Henan Glory supplies palm oil processing equipment to its overseas warehouse in Nigeria

-

A repeat Indonesian customer chose Henan Glory for palm oil press machine spare parts order

-

Nigerian client orders a 2tph drum-type palm fruit thresher from Henan Doing Nig. Co.,Ltd

-

200kg/d mini palm oil refining plant: Henan Glory’s new deal in Central Africa

-

-

Shipment Notice: 1tph compact palm oil processing line successfully dispatched to Nigeria

-

2tph Palm Oil and Palm Kernel Oil Processing Machines Project in Nigeria

-

-

-

1tph palm oil pressing machines successfully installed in Lagos, Nigeria

-

-

-

-

500kg/h palm oil and palm kernel oil processing plant project in Ghana

-

-

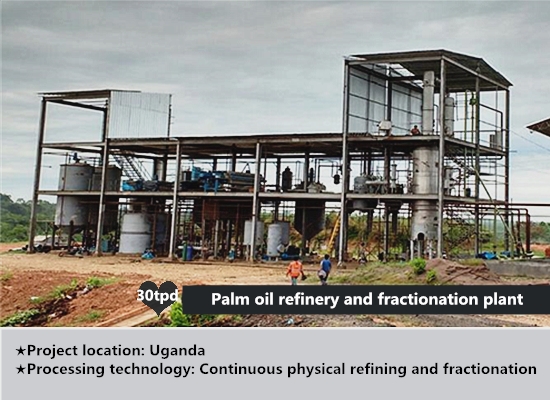

30tpd palm oil refinery and fractionation plant project successfully installed in Uganda