Ugandan customers choose to purchase 30 tons/day palm oil refining and fractionation plant from DOING

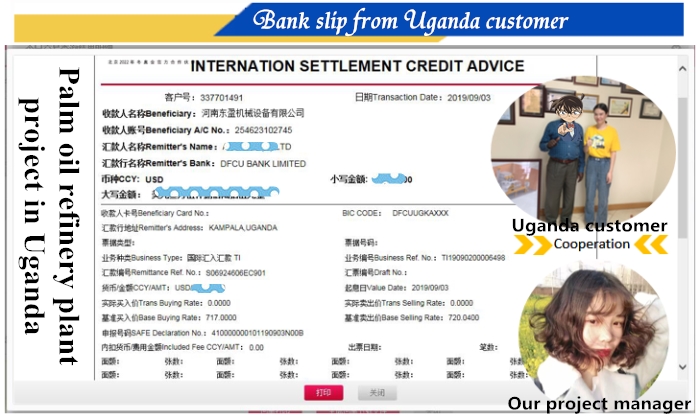

Two month ago, we received an enquiry from a Ugandan customer. He asked could you please only provide deacidification and deodorization towers in palm oil refining machine. After confirmation of various information, our engineers told him, we can do it. In the end, the Ugandan customers signed the 30 tons/day palm oil refining and fractionation plant project contract with Henan Doing Company and established the partnership.

Ugandan customers signed the 30 tons/day palm oil refining and fractionation plant project contract with Henan Doing Company

Ugandan customers signed the 30 tons/day palm oil refining and fractionation plant project contract with Henan Doing Company

Later, in the process of communication again and again, we finally learned the following information: A few years ago, our Ugandan customers bought 30tpd batch type CPO refining machine from India palm oil refining machine manufacturer. Meanwhile, imported CPO from Malaysia for refining. But due to the chemical refining consumption is too big, and the deodorization effect is not very good. The customer decided to upgrade and transform batch type palm oil refining machine into physical semi-continuous refining machine. This Ugandan customer has been in the palm oil refining business for many years, so he has a certain understanding of the refining process. He wants to add only a deacidification & deodorization tower to realize his purpose. And at the same time, he wants to add a new membrane filter to better separate palm olein and palm stearin. With more than 30 years of professional experience, decades of installation experience and the analysis of the specific situation of the customer, Henan Doing Company's engineers specially designed suitable palm oil refining solution for Ugandan customer.[Related reading: 5tpd palm oil refinery and fractionation plant project in Nigeria]

Our engineers adhere to the principle of being responsible for customers, for projects and for the reputation of DOING Company, so they made a request to the customer whether they could go to the site to check the specific situation of the project. Customers also understand this and actively arrange for our engineers' airfare and accommodation. According to the agreement, our engineers also arrived at the customer's factory on time. In order to design a more reasonable plant plan, equipment layout plan and palm oil refining process plan. Our engineers specially measured and recorded various sizes. The following are some of the photos taken by our engineers on site.

[Remarks: We generally only provide indoor equipment. For pipeline connection in outdoor public areas, it is necessary to measure and inspect according to the customer's actual situation before designing drawings.]

Our engineers are measuring and recording various data in Ugandan customer's factory

Our engineers are measuring and recording various data in Ugandan customer's factory

By reading this article, I believe that you have a new understanding of DOING Company. DOING can not only provide a complete solution of palm oil refining and fractionation machine, but also provide specific solutions according to the specific conditions of customers. If you have similar problems, please feel free to contact us, we will provide you with premium palm oil refining machines and customized palm oil refining solutions.

PREV:The manager of the Nigeria overseas office is officially on duty

PREV:The manager of the Nigeria overseas office is officially on duty

NEXT:Palm nut cracking and separating system is under installation in Nigeria

NEXT:Palm nut cracking and separating system is under installation in Nigeria

Leave A Message

If you want to know more information about Ugandan customers choose to purchase 30 tons/day palm oil refining and fractionation plant from DOING . pls kindly leave your phone number, We will back to you ASAP once we got your message.

-

Guinea client orders 1TPD electric heating palm oil refinery plant from Henan Glory

-

Henan Glory lands Guatemalan order for small scale palm oil processing equipment

-

Henan Glory supplies palm oil processing equipment to its overseas warehouse in Nigeria

-

A repeat Indonesian customer chose Henan Glory for palm oil press machine spare parts order

-

Nigerian client orders a 2tph drum-type palm fruit thresher from Henan Doing Nig. Co.,Ltd

-

200kg/d mini palm oil refining plant: Henan Glory’s new deal in Central Africa

-

-

Shipment Notice: 1tph compact palm oil processing line successfully dispatched to Nigeria

-

Cooperation with Indonesia: Henan Glory to supply 500kg/h palm oil pressing machine

-

Nigerian customer and Henan Doing sealed a deal for palm kernel oil extractors

-

2tph Palm Oil and Palm Kernel Oil Processing Machines Project in Nigeria

-

-

-

1tph palm oil pressing machines successfully installed in Lagos, Nigeria

-

-

-

-

500kg/h palm oil and palm kernel oil processing plant project in Ghana

-

-

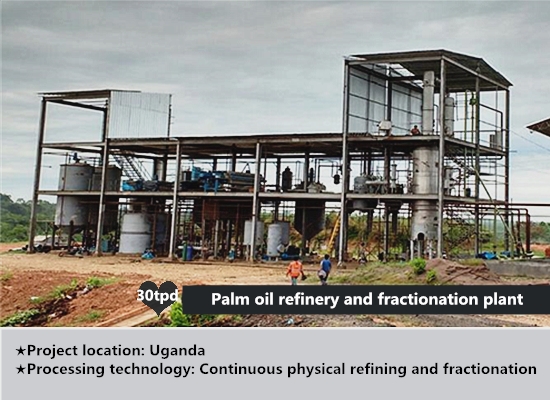

30tpd palm oil refinery and fractionation plant project successfully installed in Uganda