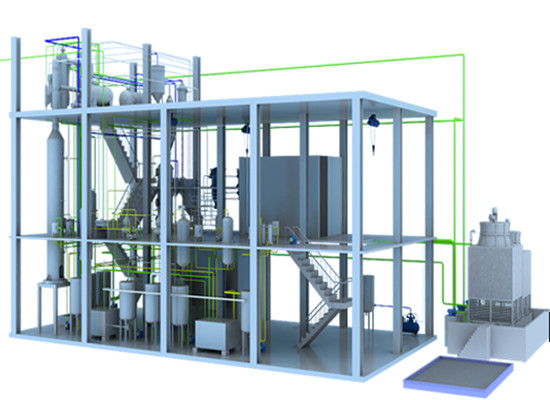

Palm oil fractionation plant technology

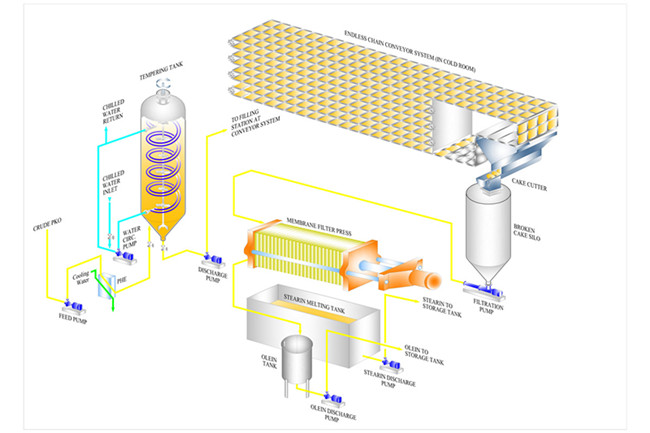

Palm oil fractionation plant flow chart

1. Advanced technology

2. Fully automatic operation by computer

3. Lower investment costs

4. With technical cooling crystallization craft, output of liquid oil is more

5. Higher purity of solid fat

6. Better economic benefit.

Henan Doing Company Machinery is a leading enterprise specialized in the technology design & research and engineering construction of oil preparation, oil refining & fractionation. After years of practice, we have won a high reputation and accumulated solid strength. We have undertaken more than 30 construction projects around the world.

We can provide design, manufacture, installation, calibration and after service of palm oil fractionation plant.

Leave A Message

If you want to know more information about Palm oil fractionation plant technology . pls kindly leave your phone number, We will back to you ASAP once we got your message.

-

Guinea client orders 1TPD electric heating palm oil refinery plant from Henan Glory

-

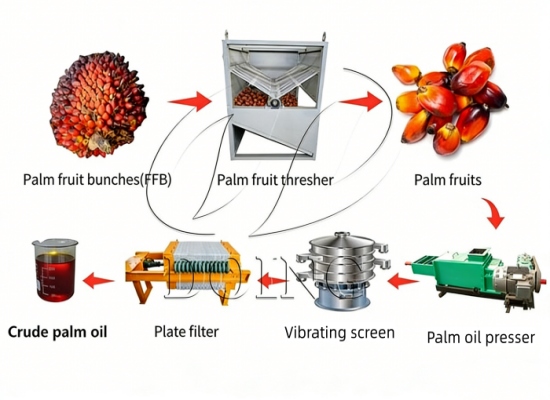

Henan Glory lands Guatemalan order for small scale palm oil processing equipment

-

Henan Glory supplies palm oil processing equipment to its overseas warehouse in Nigeria

-

A repeat Indonesian customer chose Henan Glory for palm oil press machine spare parts order

-

Nigerian client orders a 2tph drum-type palm fruit thresher from Henan Doing Nig. Co.,Ltd

-

200kg/d mini palm oil refining plant: Henan Glory’s new deal in Central Africa

-

-

Shipment Notice: 1tph compact palm oil processing line successfully dispatched to Nigeria

-

Cooperation with Indonesia: Henan Glory to supply 500kg/h palm oil pressing machine

-

Nigerian customer and Henan Doing sealed a deal for palm kernel oil extractors

-

2tph Palm Oil and Palm Kernel Oil Processing Machines Project in Nigeria

-

-

-

1tph palm oil pressing machines successfully installed in Lagos, Nigeria

-

-

-

-

500kg/h palm oil and palm kernel oil processing plant project in Ghana

-

-

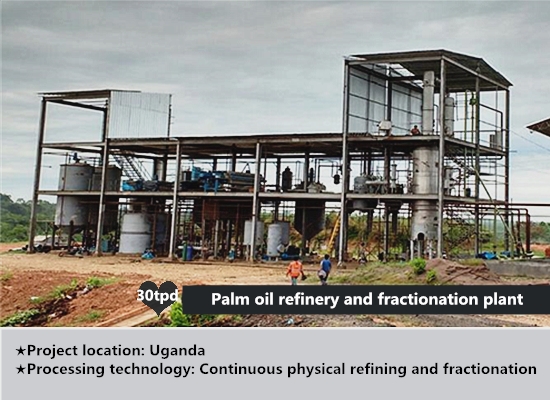

30tpd palm oil refinery and fractionation plant project successfully installed in Uganda