Palm kernel oil extraction plant

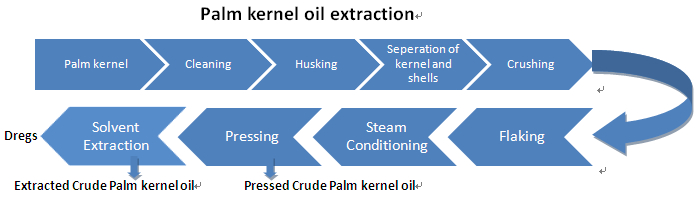

Palm kernel oil extraction

Palm Kernel Oil Extraction

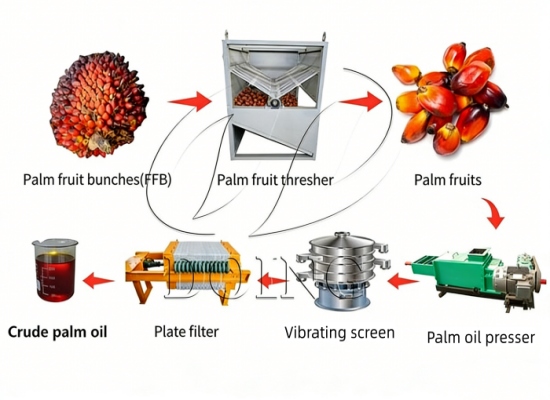

Proper kernel pre-treatment is necessary to efficient palm kernel oil extraction efficiently. The feed kernels must first be cleaned of foreign materials that may cause damage to the pressing, increasing maintenance costs and down time, and contamination of products. Magnetic separators commonly are installed to remove metal debris, while vibrating screens are used to sieve sand, stones or other undesirable materials.

Palm Kernel Oil Extraction

The kernel flakes are then conveyed to a stack cooker for steam conditioning, the purpose of which is to:

a> adjust the moisture content of the meal to an optimum level;

b> rupture cell walls (initiated by rolling);

c> reduce viscosity of oil;

· coagulate the protein in the meal to facilitate separation of the oil from protein materials.

Palm Kernel Oil Extraction

The meal flows from the top compartment down to the fifth compartment in series. At each stage a mechanical stirrer agitates the meal. Steam trays heat the cookers, and live steam may be injected into each compartment when necessary. The important variables are temperature, retention time and moisture content. In the palm kernel, the meals are normally cooked to a moisture content of 3 percent at 104-110°C.

Henan Doing Machinery , we have been concentrated on palm oil machine for 40years. If u need anything more about palm oil. Please contact us.

NEXT:Palm kernel oil

NEXT:Palm kernel oil

Leave A Message

If you want to know more information about Palm kernel oil extraction plant . pls kindly leave your phone number, We will back to you ASAP once we got your message.

-

Successful order for 1tph palm oil processing equipment from a customer in Nigeria

-

Guinea client orders 1TPD electric heating palm oil refinery plant from Henan Glory

-

Henan Glory lands Guatemalan order for small scale palm oil processing equipment

-

Henan Glory supplies palm oil processing equipment to its overseas warehouse in Nigeria

-

A repeat Indonesian customer chose Henan Glory for palm oil press machine spare parts order

-

Nigerian client orders a 2tph drum-type palm fruit thresher from Henan Doing Nig. Co.,Ltd

-

200kg/d mini palm oil refining plant: Henan Glory’s new deal in Central Africa

-

-

Shipment Notice: 1tph compact palm oil processing line successfully dispatched to Nigeria

-

Cooperation with Indonesia: Henan Glory to supply 500kg/h palm oil pressing machine

-

2tph Palm Oil and Palm Kernel Oil Processing Machines Project in Nigeria

-

-

-

1tph palm oil pressing machines successfully installed in Lagos, Nigeria

-

-

-

-

500kg/h palm oil and palm kernel oil processing plant project in Ghana

-

-

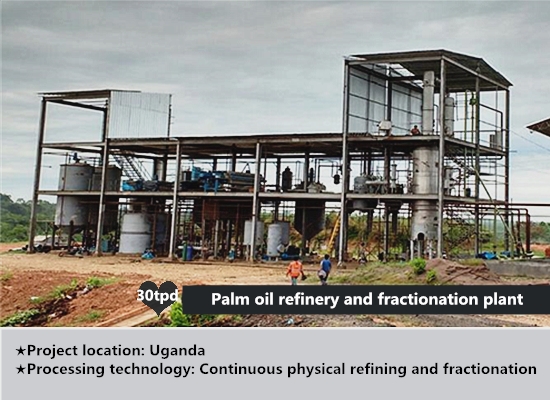

30tpd palm oil refinery and fractionation plant project successfully installed in Uganda