20tpd palm oil refinery plant exported to Indonesia

Heat Conduction Furnace: 1 set Offer enough thermo for the refining sections.

Steam Generator: 1 set Produce steam for the workshop

Refining Pot: 2 sets Remove the gum, phosphoric acid etc,

Decolorizing Pot: 1 set Remove the color from neutralized oil

Deodorizing Pot: 1 set Remove the solvent, smell, water from decolorized oil

Other Auxiliary Equipments: Hot water Tank, Bleaching earth Tank, Air compressor, pumps, filters, Valves, Electricity Control Cabinet, etc.

(This small scale palm oil refinery plant is based on chemical refining technique. The main crude palm oil refinery plant includes degumming pot, refining pot, leaf filter, decoloring pot and more.)

The main equipment of crude palm oil refinery plant includes degumming pot, refining pot, leaf filter, decoloring pot and more

Other machines and spare parts of 20tpd palm oil refinery plant

Main Stages of Palm Oil Refinery Process

Degumming section :

Degumming is the first and basic step in the small scale palm oil refinery plant, degumming process aims to removing the gum impurities in the crude oil to make it suitable for further refinery process, hydration degumming and special acid degumming are the two main methods.

Deacidification section :

The deacidification system uses versatile neutralization technology, which is developed to deal with oilseeds of different species and qualities in the small scale palm oil refinery plant, it can realize both degumming and neutralization processes by adding alkali, water and acid, then with FFA, crude phospholipids and moisture all removed, the oil and by products (soap foot, phospholipids) are separated.

Bleaching section :

The oil bleaching is also named decolorization in small scale palm oil refinery plant. This process’s main purpose is to remove the product of oxidation, pigments, phospholipids, soap materials from the oil. In the oil refinery plant, this process can improve the oil color as well as supplies high quality oil for the deodorization process.

Deodorization section :

Deodorization section is very crucial in small scale palm oil refinery plant in first grade oil production as it improves the flavor of the oil; the quality of deodorization equipment has great effect to the oil quality.

These years, we have exported a lot of equipment for its palm oil and palm kernel oil productions and gained rich experiences in equipment installation and onsite commissioning for Nigeria market, Kenya market, Malaysia martket , Indoesia market and so on. The price of our palm oil refinery plant, small or large, is the most favorable in the market and the quality of our machinery is completely guaranteed. If you want to know more details about the turnkey palm oil mill plant projects, turnkey palm kernel oil mill plant projects. Please contact us, we can offer more than you expected!

PREV:Palm oil extraction equipment manufacturer & supplier & exporter

PREV:Palm oil extraction equipment manufacturer & supplier & exporter

NEXT:Cote d'Ivoire 1tph palm kernel oil expeller machine is ready for delivery

NEXT:Cote d'Ivoire 1tph palm kernel oil expeller machine is ready for delivery

Leave A Message

If you want to know more information about palm oil extraction machine. pls kindly leave your phone number, We will back to you ASAP once we got your message.

- QDo you want to buy machine?

- Yes, I want to buy machine.

- No, I want to learn more in advance.

- QWhat oil seeds do you want to process?

- Palm fruit

- Palm kernel/nut

- Peanut/Groundnut

- Soybean/Soya bean

- Sunflower seed

- Cottonseed

- Rapeseed/Canola

- Dried coconut

- Rice bran

- Corn germ

- More than two oilseeds:

- Other:

- QHow many tons palm fruit bunches will you process per day?

- 1-10 tons per day

- 10-30 tons per day

- 30-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

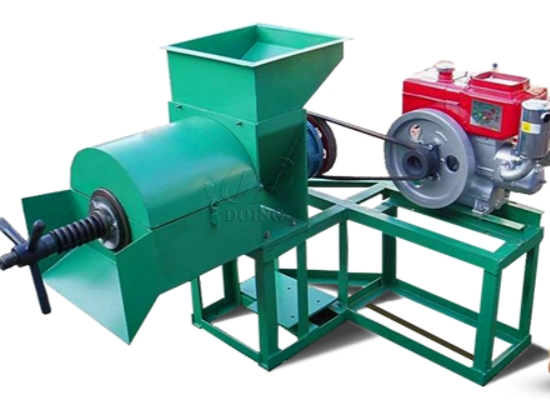

- Palm oil presser

- Other single machine (thresher, clarification tank, vibrating screen, filter...)

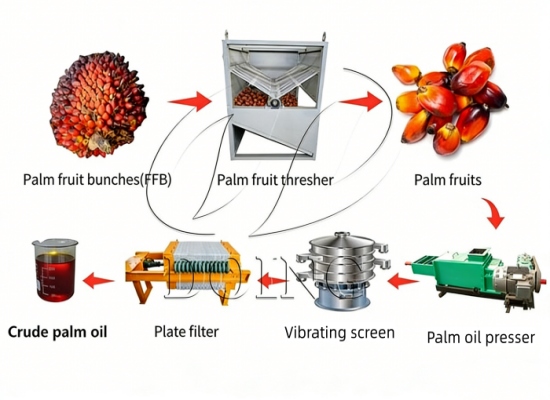

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QWhat machine do you want?

- Palm oil pressing line (from FFB to crude oil)

- Palm oil refining line (to produce refined, bleached, deodorized oil)

- Palm oil bottling / filling line

- QHow many tons oil seeds will you process per day?

- 1-20 tons per day

- 20-50 tons per day

- 50-100 tons per day

- QWhat machine do you want?

- Oil presser

- Other single machine (cracker, crusher, roaster, filter...)

- Oil pressing line (from seeds to crude oil)

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil presser

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

- QWhat machine do you want?

- Oil pressing line (from seeds to crude oil)

- Oil solvent extraction line

- Oil refining line (to produce refined, bleached, deodorized oil)

- Oil bottling / filling line

-

A Cameroonian client successfully booked a 500kg/h palm oil processing line

-

Successful order for 1tph palm oil processing equipment from a customer in Nigeria

-

Guinea client orders 1TPD electric heating palm oil refinery plant from Henan Glory

-

Henan Glory lands Guatemalan order for small scale palm oil processing equipment

-

Henan Glory supplies palm oil processing equipment to its overseas warehouse in Nigeria

-

A repeat Indonesian customer chose Henan Glory for palm oil press machine spare parts order

-

Nigerian client orders a 2tph drum-type palm fruit thresher from Henan Doing Nig. Co.,Ltd

-

200kg/d mini palm oil refining plant: Henan Glory’s new deal in Central Africa

-

-

Shipment Notice: 1tph compact palm oil processing line successfully dispatched to Nigeria

-

2tph Palm Oil and Palm Kernel Oil Processing Machines Project in Nigeria

-

-

-

1tph palm oil pressing machines successfully installed in Lagos, Nigeria

-

-

-

-

500kg/h palm oil and palm kernel oil processing plant project in Ghana

-

-

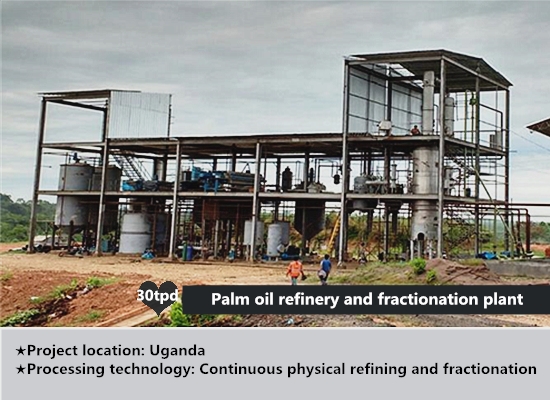

30tpd palm oil refinery and fractionation plant project successfully installed in Uganda