1TPD palm kernel oil refinery plant

Factory direct sale contact number

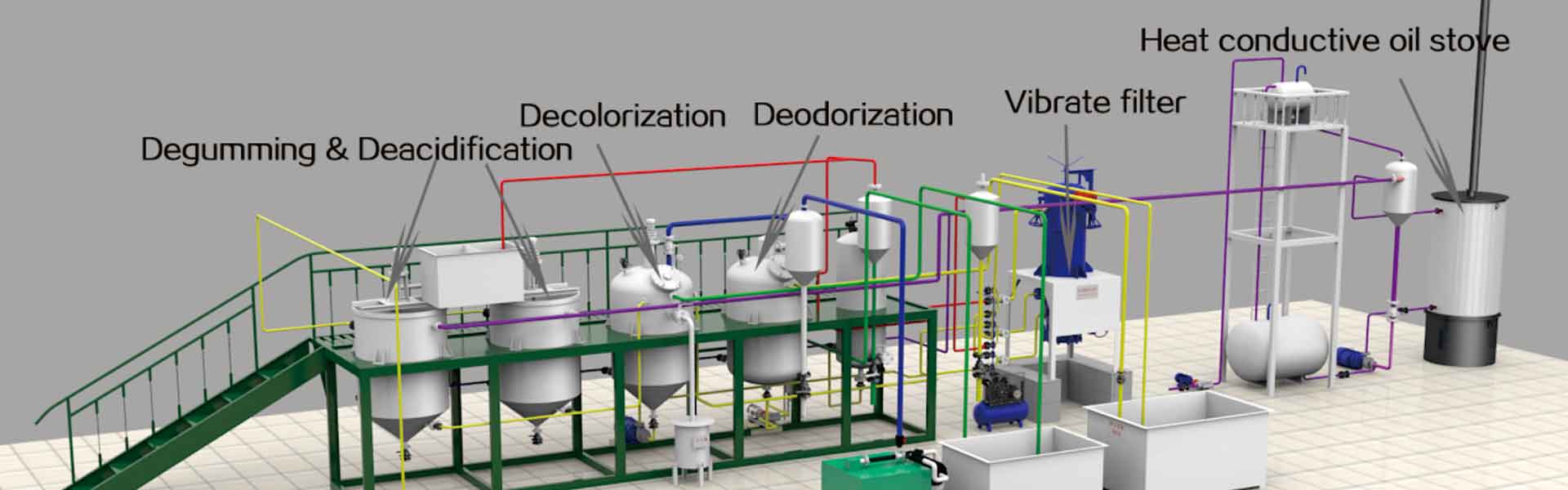

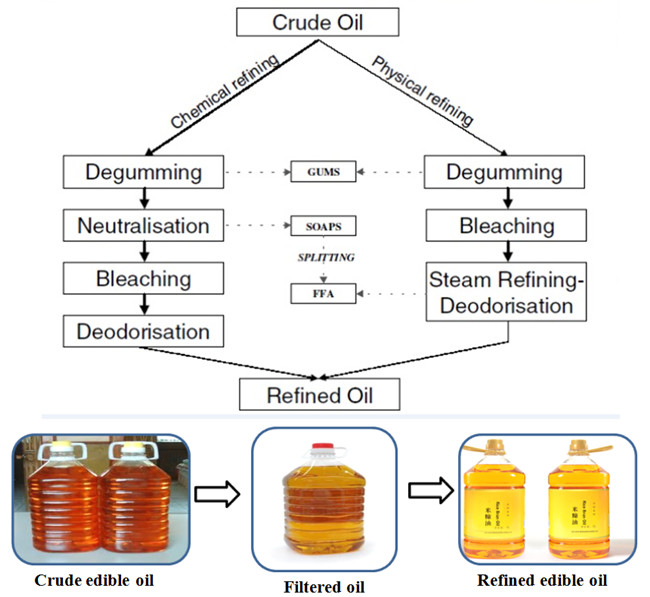

Now, 1TPD palm kernel oil refinery plant is developing very quickly, and taking more and more bigger market share.1TPD palm kernel oil refinery plant is based on the different usage and requirements, utilizing the physical methods and chemical processes to get rid of the harmful impurities and needless substance in the crude edible palm kernel oil,getting standard edible palm kernel oil.So 1TPD palm kernel oil refinery plant is the major equipment to refine crude edible palm kernel oil.

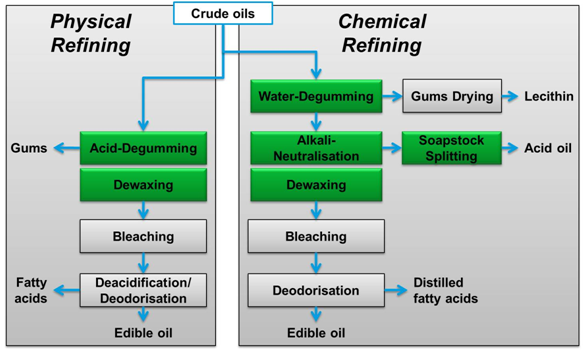

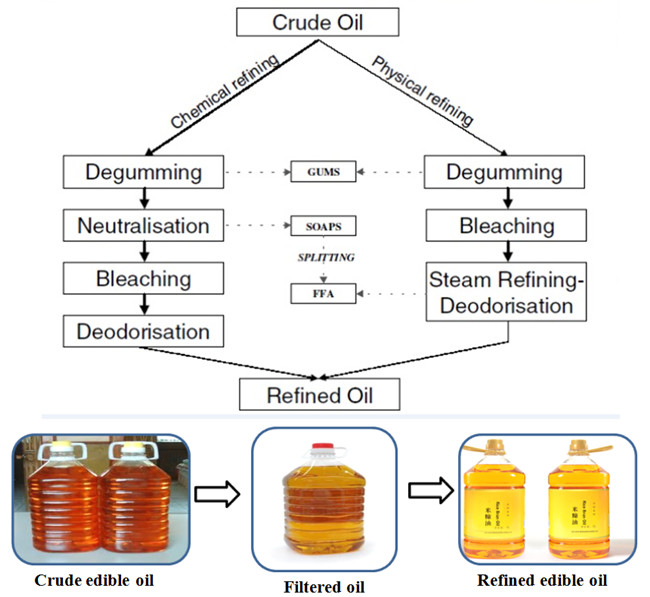

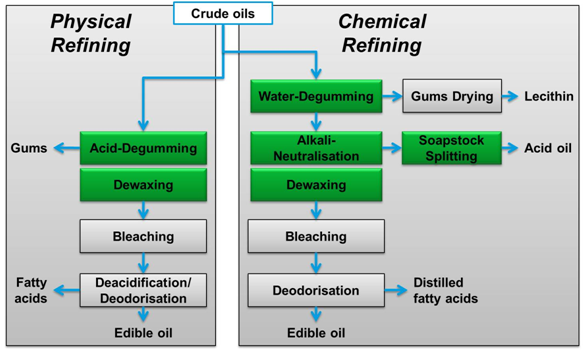

Physical refining and chemical refining

1TPD palm kernel oil refinery plant specifications:

Name:palm kernel oil refinery plant

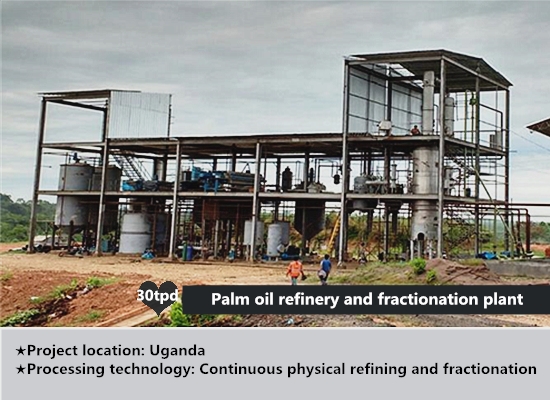

Capacity:1TPD,2TPD,3TPD,5TPD,10TPD,20TPD,30TPD.....600TPD

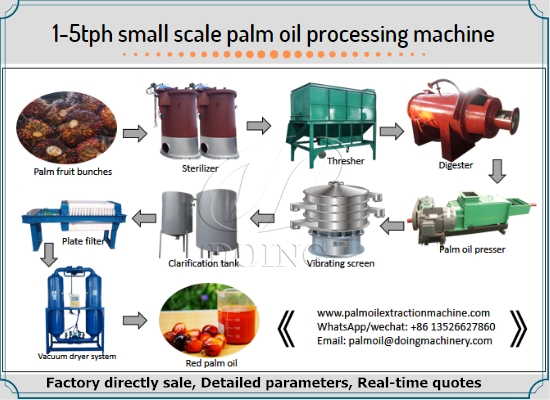

Application:1tpd palm kernel oil refinery plant can used to refine various kinds of edible oil,such as soybean oil,corn oil,sunflower oil,rapeseed oil,rice bran oil,palm oil,and so on.

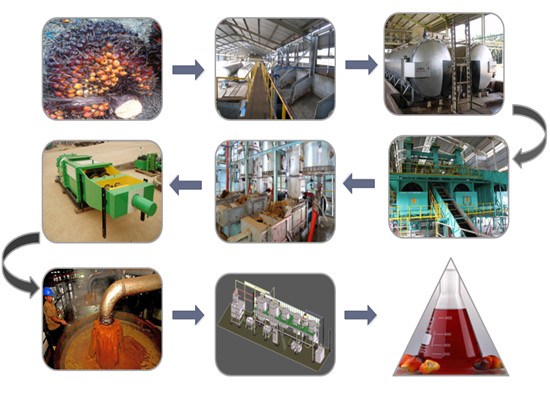

The following is the basic refinery process of crude palm kernel oil:

Crude palm kernel oil → Degumming → Deacidification → Decolorization → Deodorization → Refined palm kernel oil

1TPD palm kernel oil refinery plant

Main Refining Processes for 1TPD palm kernel oil refinery plant

1. Degumming Process of 1TPD palm kernel oil refinery plant:

Some impurity, such as Phospholipid, gum, and protein, can be dissolved into oil when there is no water, but once there is water in oil, these impurities can be dissolved into water. So, in degumming section, we use the hot water to wash crude oil for two-three times to remove these impurities.

2. Neutralizing/Neutralization Process of 1TPD palm kernel oil refinery plant:

The crude oil is fed into the neutralizer and mixed with small amounts of degumming agent such as phosphoric acid to help remove gums.Free fatty acids are removed from the oil by adding caustic soda and heating it at 60˚ then stirring the mixture. Heating helps caustic soda to react with the fatty acids to form the soap material. Once the soap material settles in the neutralizer machine, it is collected with soap pans while the oil is washed with water to remove any traces of soap or any alkaline particles.

3. Decolorizing Process of 1TPD palm kernel oil refinery plant:

The neutralized oil requires bleaching to get rid of colors. This is done by adding the oil in a bleacher machine of 1tpd palm kernel oil refinery plant whereby it is heated to remove any moisture it might have and then mixed with earth bleach and activated carbon. These two properties absorb any colors after which the oil is passed through a filter to separate oil from earth bleach and carbon. The result is golden light oil.

4. Deodorizing Process of 1TPD palm kernel oil refinery plant:

The golden light oil has unpleasant odors which result from materials such as aldehydes, ketones, tocopherols and phenols among other odiferous elements. Deodorizing process in 1tpd palm kernel oil refinery plant helps remove these odors by adding the oil in the deodorizer and heating it above at very high temperature ranging from 110˚ to 220˚ and under very high vacuum. This process helps get rid of all odors.

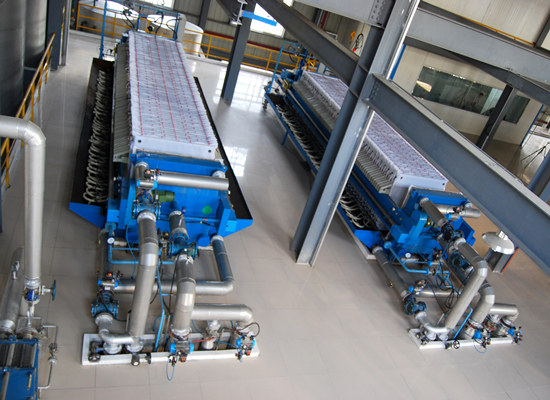

Large scale palm kernel oil refinery plant

Advantages of 1TPD palm kernel oil refinery plant:

Wide application: suitable for various crude vegetable oil, even animal oil, fish oil, etc.

Low investment: need less investment, and cost recovering time is also short.

Less land request: even 50m2 workshop will be ok.

Easy operation: After our short time professional training, your workers can operate the 1tpd palm kernel oil refinery plant well.

Physical refining and chemical refining

Name:palm kernel oil refinery plant

Capacity:1TPD,2TPD,3TPD,5TPD,10TPD,20TPD,30TPD.....600TPD

Application:1tpd palm kernel oil refinery plant can used to refine various kinds of edible oil,such as soybean oil,corn oil,sunflower oil,rapeseed oil,rice bran oil,palm oil,and so on.

The following is the basic refinery process of crude palm kernel oil:

Crude palm kernel oil → Degumming → Deacidification → Decolorization → Deodorization → Refined palm kernel oil

1TPD palm kernel oil refinery plant

1. Degumming Process of 1TPD palm kernel oil refinery plant:

Some impurity, such as Phospholipid, gum, and protein, can be dissolved into oil when there is no water, but once there is water in oil, these impurities can be dissolved into water. So, in degumming section, we use the hot water to wash crude oil for two-three times to remove these impurities.

2. Neutralizing/Neutralization Process of 1TPD palm kernel oil refinery plant:

The crude oil is fed into the neutralizer and mixed with small amounts of degumming agent such as phosphoric acid to help remove gums.Free fatty acids are removed from the oil by adding caustic soda and heating it at 60˚ then stirring the mixture. Heating helps caustic soda to react with the fatty acids to form the soap material. Once the soap material settles in the neutralizer machine, it is collected with soap pans while the oil is washed with water to remove any traces of soap or any alkaline particles.

3. Decolorizing Process of 1TPD palm kernel oil refinery plant:

The neutralized oil requires bleaching to get rid of colors. This is done by adding the oil in a bleacher machine of 1tpd palm kernel oil refinery plant whereby it is heated to remove any moisture it might have and then mixed with earth bleach and activated carbon. These two properties absorb any colors after which the oil is passed through a filter to separate oil from earth bleach and carbon. The result is golden light oil.

4. Deodorizing Process of 1TPD palm kernel oil refinery plant:

The golden light oil has unpleasant odors which result from materials such as aldehydes, ketones, tocopherols and phenols among other odiferous elements. Deodorizing process in 1tpd palm kernel oil refinery plant helps remove these odors by adding the oil in the deodorizer and heating it above at very high temperature ranging from 110˚ to 220˚ and under very high vacuum. This process helps get rid of all odors.

Large scale palm kernel oil refinery plant

Advantages of 1TPD palm kernel oil refinery plant:

Wide application: suitable for various crude vegetable oil, even animal oil, fish oil, etc.

Low investment: need less investment, and cost recovering time is also short.

Less land request: even 50m2 workshop will be ok.

Easy operation: After our short time professional training, your workers can operate the 1tpd palm kernel oil refinery plant well.

Leave A Message

If you want to know more information about 1TPD palm kernel oil refinery plant. pls kindly leave your phone number, We will back to you ASAP once we got your message.

Palm kernel oil refinery

Products

palm oil mill plant projects

Palm Oil Extraction FAQ

-

How to start a palm oil milling and processing plant?

How to start a palm oil milling and processing plant?

-

How to start a palm oil processing business in nigeria?

How to start a palm oil processing business in nigeria?

-

How to produce refined vegetable oil from palm kernel oil?

How to produce refined vegetable oil from palm kernel oil?

-

What are the steps in palm oil production?

What are the steps in palm oil production?

-

Why palm oil processing equipment is the key to determining palm oil quality?

Why palm oil processing equipment is the key to determining palm oil quality?

-

What are the mill methods of palm nut oil? What are their different?

What are the mill methods of palm nut oil? What are their different?

-

Why is palm oil deacidified during the refining process? How to perform deacidification?

Why is palm oil deacidified during the refining process? How to perform deacidification?

-

What is the working principle of palm kernel cracker and separating machine?

What is the working principle of palm kernel cracker and separating machine?

recommend products